Rotomolding Revolution: Pioneering Advancements in Plastic Production

Inside the arena of plastic-type material production, reaching preciseness and excellence in item design and style and generation is actually a frequent pursuit. A single technique that has surfaced as being a video game-changer in connection with this is rotational molding. Through its special process and thorough architectural, rotational molding enables the creation of plastic-type material merchandise with unmatched accuracy and precision and quality.

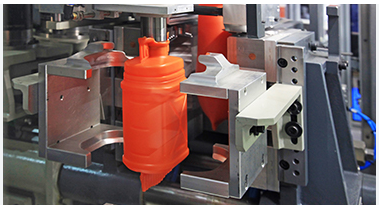

Rotational molding, also referred to as Rotomolding, is really a manufacturing approach that concerns the rotation of the fungus while liquid plastic is slowly rotated, covering the inner work surface and gradually solidifying in to the desired condition. This method provides for the development of complex, hollow plastic-type material goods with excellent uniformity and precision.

One of many key features of rotational molding is its capability to create sizeable, effortless constructions. In contrast to other plastic-type material manufacturing techniques that involve a number of pieces or seams, rotational molding generates a single, single product or service. This seamless building not just enhances the visual charm but also increases the structural integrity and durability from the final product or service.

Accuracy technology is in the middle of rotational molding. This process consists of carefully balancing the rotational velocity, heat, and the right time to obtain the ideal effects. With accurate power over these parameters, producers can ensure steady wall fullness, consistent circulation of materials, and specific duplication of elaborate particulars. This amount of accuracy is specially useful for businesses for example vehicle, aerospace, and health-related, in which limited tolerances and specific specifications are necessary.

Moreover, rotational molding gives design mobility that permits for the development of intricate shapes and geometries. The mold employed in rotational molding might be custom-intended to allow for various design and style specifications. This overall flexibility opens up a arena of possibilities for developers and technical engineers to push the boundaries of ingenuity and innovation. From intricate curves to complex interior features, rotational molding can do it all.

Additionally, rotational molding permits utilizing a number of plastic supplies, such as polyethylene, polypropylene, and Pvc material. This overall flexibility in materials choice enables suppliers to modify the attributes of your ultimate item to satisfy certain requirements, including compound resistance, influence energy, or Ultra violet stability. With the ability to decide on the most suitable materials for every single application, rotational molding makes certain that precision-manufactured merchandise are not just visually pleasing but additionally functionally outstanding.

To conclude, accuracy technology is the spine of rotational molding, an activity that allows the creation of plastic-type material goods with exceptional precision and top quality. From seamless design to develop flexibility and fabric adaptability, rotational molding provides a myriad of benefits making it an ideal decision in a variety of industries. As modern technology and architectural carry on and improve, rotational molding will certainly perform a much more considerable position in accomplishing flawlessness and preciseness in plastic-type material developing.